Introduction to Injection Molding

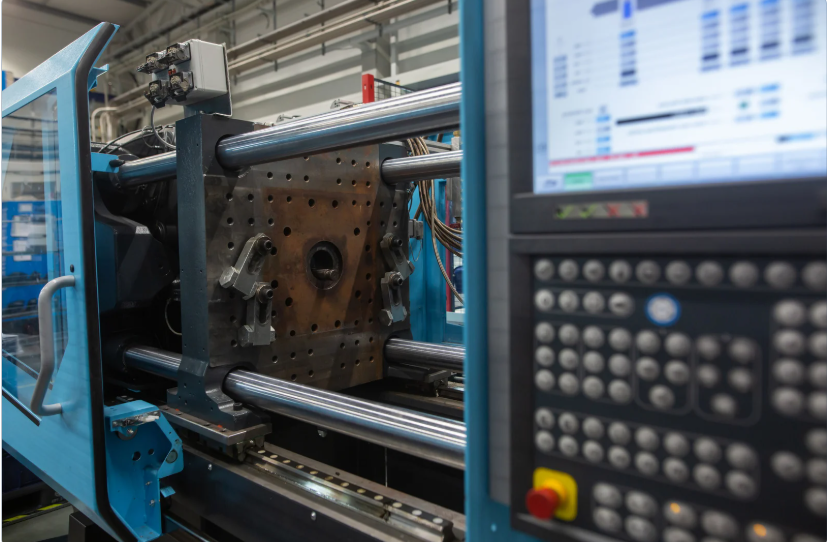

Injection molding is a manufacturing process that has revolutionized the production of plastic components. This method allows for the creation of intricate designs and high-volume production, making it a popular choice across various industries. In this article, we will explore the fundamentals of injection molding, its advantages, and its applications.

What is Injection Molding?

At its core, injection molding involves injecting molten material into a mold to create a specific shape. This process can be used with various materials, including thermoplastics and thermosetting plastics. The versatility of injection molding makes it suitable for producing everything from automotive parts to household items.

The Injection Molding Process

The injection molding process can be broken down into several key steps:

- Material Preparation: Raw plastic pellets are fed into a hopper and heated until they melt.

- Injection: The molten plastic is injected into a mold under high pressure.

- Cooling: The plastic cools and solidifies within the mold.

- Demolding: Once cooled, the mold opens, and the finished part is ejected.

Advantages of Injection Molding

Injection molding offers numerous benefits, making it a preferred choice for manufacturers:

- High Efficiency: Once the mold is created, the process can produce large quantities of parts quickly.

- Precision and Consistency: Injection molding allows for tight tolerances and uniformity in production.

- Versatility: The process can accommodate a wide range of materials and designs.

- Minimal Waste: The method generates less scrap compared to other manufacturing processes.

Applications of Injection Molding

Injection molding is used in various sectors, including:

- Automotive: Parts like dashboards, bumpers, and interior components.

- Consumer Goods: Items such as containers, toys, and appliances.

- Medical Devices: Components for syringes, surgical instruments, and more.

- Electronics: Housings for devices like smartphones and computers.

Cost-Effectiveness in Production

One of the most compelling reasons to choose injection molding is its cost-effectiveness. While the initial investment in mold creation can be high, the long-term savings in production costs make it worthwhile. Mass production leads to lower per-unit costs, making it an attractive option for manufacturers.

Factors Influencing Injection Molding Costs

Several factors can affect the overall cost of injection molding:

| Factor | Impact on Cost |

|---|---|

| Mold Design | Complex designs can increase initial costs but may reduce production time. |

| Material Choice | Different materials have varying costs, affecting overall production expenses. |

| Production Volume | Higher volumes generally lead to lower per-unit costs. |

| Machine Setup | Setup costs can vary based on the machine and process used. |

Choosing the Right Injection Molding Partner

When selecting a manufacturing partner for injection molding, consider the following:

- Experience: Look for a company with a proven track record in the industry.

- Capabilities: Ensure they can handle your specific production needs.

- Quality Assurance: A commitment to quality is crucial for consistent results.

Innovations in Injection Molding

The injection molding industry is continually evolving. Recent advancements include:

- Automation: Increased use of robotics for efficiency and precision.

- 3D Printing: Integration of additive manufacturing for rapid prototyping.

- Eco-Friendly Materials: Development of sustainable materials for reduced environmental impact.

The Future of Injection Molding

As technology advances, the future of injection molding looks promising. Innovations in materials, processes, and automation will continue to drive efficiency and sustainability in the industry. Manufacturers who adapt to these changes will likely thrive in the competitive landscape.

Conclusion

Injection molding is a vital process in modern manufacturing, offering numerous advantages in efficiency, precision, and cost-effectiveness. By understanding the intricacies of this method, businesses can make informed decisions and optimize their production strategies. For more insights, consider exploring resources on China injection molding and plastic mold.